Case study - Steam solidify technology

Case Sharing I Application and practice of Steam solidify technology in trenchless repair of pressure pipeline

(一)Project background

In this project, DN500 cast iron water pipe under a bridge in a certain area of Nanjing was repaired with trenchless lining, crossing the road and bridge, and the bridge section was about 30 meters. The original pipe in the whole repair section had three 45 degree corners, two of which were forward and the other was reverse. In view of the current situation of the pipeline, there are problems such as peeling off of the pipe skin, corrosion and leakage in many places, serious corrosion of the pipe wall, large population of surrounding residents, water can not be cut off for a long time, and the traditional excavation and replacement method will pose a potential threat to the safety of the bridge body, which is difficult to repair. In order to ensure the structural strength and service life of the original pipeline, after comparing various construction methods and considering the actual factors on site, Finally, it was decided to use steam curing technology for structural repair, and work pits were set at the north and south ends to ensure the safety of the bridge body and bridge floor. This time, steam curing method was adopted for repair, steam was used as the heat source, and the hose material was glass fiber-reinforced lined pipe for Tuohong drinking water trenchless repair (model: THCIPP-DW).

(二) Steam curing technology

(1) Material preparation: Choose green, environmentally friendly Tuohong drinking water trenchless repair glass fiber reinforced lining pipe (model: THCIPP-DW) without styrene. The material has passed Jiangsu and Zhejiang drinking water standard test.

(2) Pipeline pretreatment: Use high pressure water gun to clean the inner wall of the pipeline to ensure no impurities and create a good environment for materials to enter.

Before cleaning (left) - After cleaning (Right)

(3) Steam curing: the material hose is sent into the pipeline and heated to the set temperature with steam to make the material quickly cure and form a high-strength lining layer.

(4) Port treatment: The hose ports in the north and south working pits are cut to ensure that they are smooth, and the sealing double expansion ring is installed at the connection between the material and the inner wall of the original pipe to enhance the tightness.

(2) Pipeline pretreatment: Use high pressure water gun to clean the inner wall of the pipeline to ensure no impurities and create a good environment for materials to enter.

Before cleaning (left) - After cleaning (Right)

(3) Steam curing: the material hose is sent into the pipeline and heated to the set temperature with steam to make the material quickly cure and form a high-strength lining layer.

(4) Port treatment: The hose ports in the north and south working pits are cut to ensure that they are smooth, and the sealing double expansion ring is installed at the connection between the material and the inner wall of the original pipe to enhance the tightness.

(三) Construction process

Construction time: Date: 2024.9.3, Time: 22:00-6:00

Construction location: Nanjing

Nanjing Huarui Municipal Engineering Co., Ltd. works at night to minimize the impact on the surrounding environment. Professional team operation ensures precise control of steam temperature and pressure for an efficient and safe curing process.

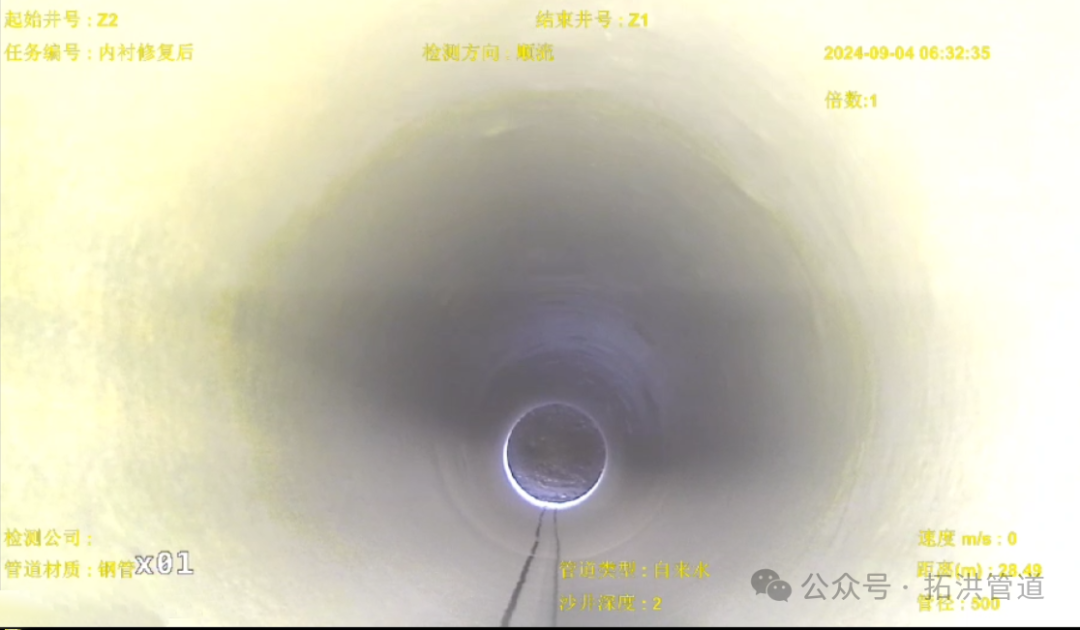

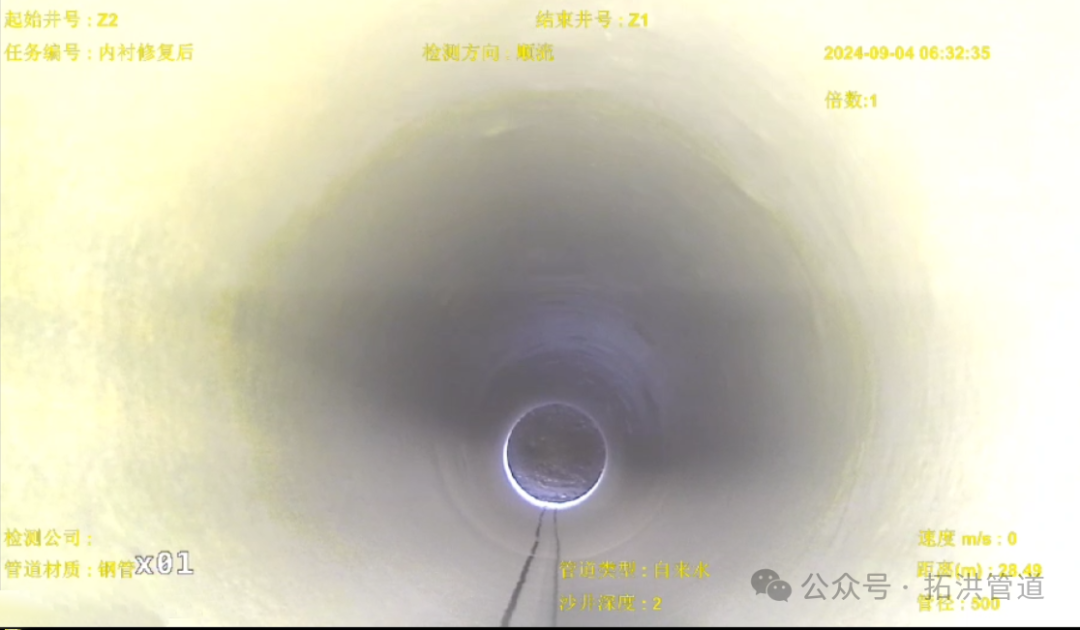

(四) Display of achievements

The steam curing repair of the pipeline not only solves the leakage problem, but also significantly prolongs the service life of the pipeline because of its structural repair, and increases the stability of the water supply system.

Conclusion

Our steam curing technology can well meet the repair needs of the whole structure of the water supply pipeline, fast speed, long distance, easy bending and cost reduction, and is suitable for pipes of various materials, including cast iron pipe, steel pipe, concrete pipe and so on. Contribute to the long-term stability of the urban water supply network. At the same time, we also thank users for their support and trust in Hongzai, and we will continue to work hard to provide users with better quality and reliable pipeline repair solutions. If you have any questions or needs regarding steam curing technology or other pipe repair technologies, please feel free to contact us and we will be happy to help you.

Conclusion

Our steam curing technology can well meet the repair needs of the whole structure of the water supply pipeline, fast speed, long distance, easy bending and cost reduction, and is suitable for pipes of various materials, including cast iron pipe, steel pipe, concrete pipe and so on. Contribute to the long-term stability of the urban water supply network. At the same time, we also thank users for their support and trust in Hongzai, and we will continue to work hard to provide users with better quality and reliable pipeline repair solutions. If you have any questions or needs regarding steam curing technology or other pipe repair technologies, please feel free to contact us and we will be happy to help you.